| News |

Baldur Coatings AS have become agents for Beneq in Norway. Contact us for more information. |

Applications

The technique has till now made a large scale breakthrough within at least three areas:

- High k-materials for microelectronics: The technique is used to day to produce insulating layers in transistors and memory chips. Implementation of the technique has been an enabling factor for the 65, and now 45 nm technologies. The traditional insulating SiOx layer in transistors is now replaced by Al2O3 or HfO2 produced by ALD.

- Production of inorganic electroluminescent displays: The ALD technique was used for production of solid state electroluminescent displays already in the middle of 1980ies. Both the active material and the insulating material may be produced by ALD during one pumpdown. The ALD technique enabled production of such robust displays without the need of cleanroom since the films cover impurities evenly and ensures pinhole free films.

- Corrosion protection: The ALD technique is superior in covering complex surface geometries in a complete manner. It is therefore the prime choice for corrosion protection of components by covering with Al2O3, TiN or other special compounds. The technique is presently used for anti tarnish protection of silver jewelry by the nSilver process.

Jewelries that does not tarnish

Processes are developed within several areas such as:

- Diffusion barriers: By application of thin multilayered structures made by ALD one can build diffusion barriers with superior properties for gas and fluids. The aim is to develop plastics with diffusion properties of glass.

- Fuel cells: The ALD technique is superior for deposition of pinhole free films, which is important in development of solid state electrolytes within fuel cells and batteries. By reducing the thickness of the electrolyte, the flux can be increased.

- Transparent conducting materials: The ALD technique can be used for deposition of transparent conducting oxides such as doped In2O3 and ZnO. Such materials are used in solar cells, flat panel displays and in sensors.

- Nanoparticles: The ALD technique can be used for modification of nanoparticles in order to increase or decrease their reactivity. The ALD technique is good for production of core shell structures of nanoparticles.

- Optics The ALD technique is very suitable for production of gradient free films on large surfaces. Multilayered structures of ALD grown materials are applicable for production of optical filters on complex substrates.

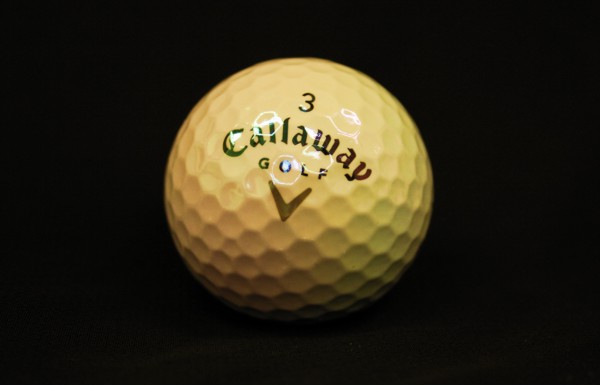

- Self cleaning surfaces: A thin layers of ALD grown TiO2 will provide a surface with self cleaning properties. There is still need for some UV light, but research is ongoing to make the material active in normal lighting conditions.

- Batteries: By application of ALD one can enable solid state electrolytes in thin film batteries. This is a class of batteries which show remarkable low loss of capacity with usage, and increased safety.

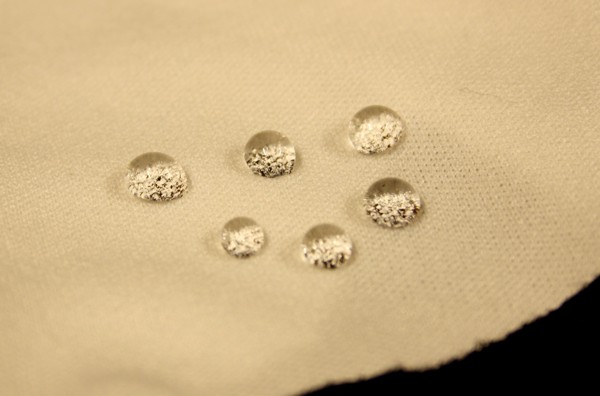

- Surface wetting: It is the terminating surface that determines the wetting properties of the material. By application of the ALD technique, one is able to control these properties without altering the structure or the appearance of the surface.

A self cleaning golf ball produced by ALD

The ALD technique is suitable for production of most types of inorganic materials (oxides, nitrides, sulphides), some types of organic materials, as well as a range of organic- inorganic hybrid materials. The ALD technique can also be used for deposition of W, as well as some noble metals Pt, Ir, Rh, Cu.

This is only meant as a limited overview and we urge you to get in touch for more information about possibilities within your applications.

An absorbing cloth becomes superhydrofobic by use of ALD.